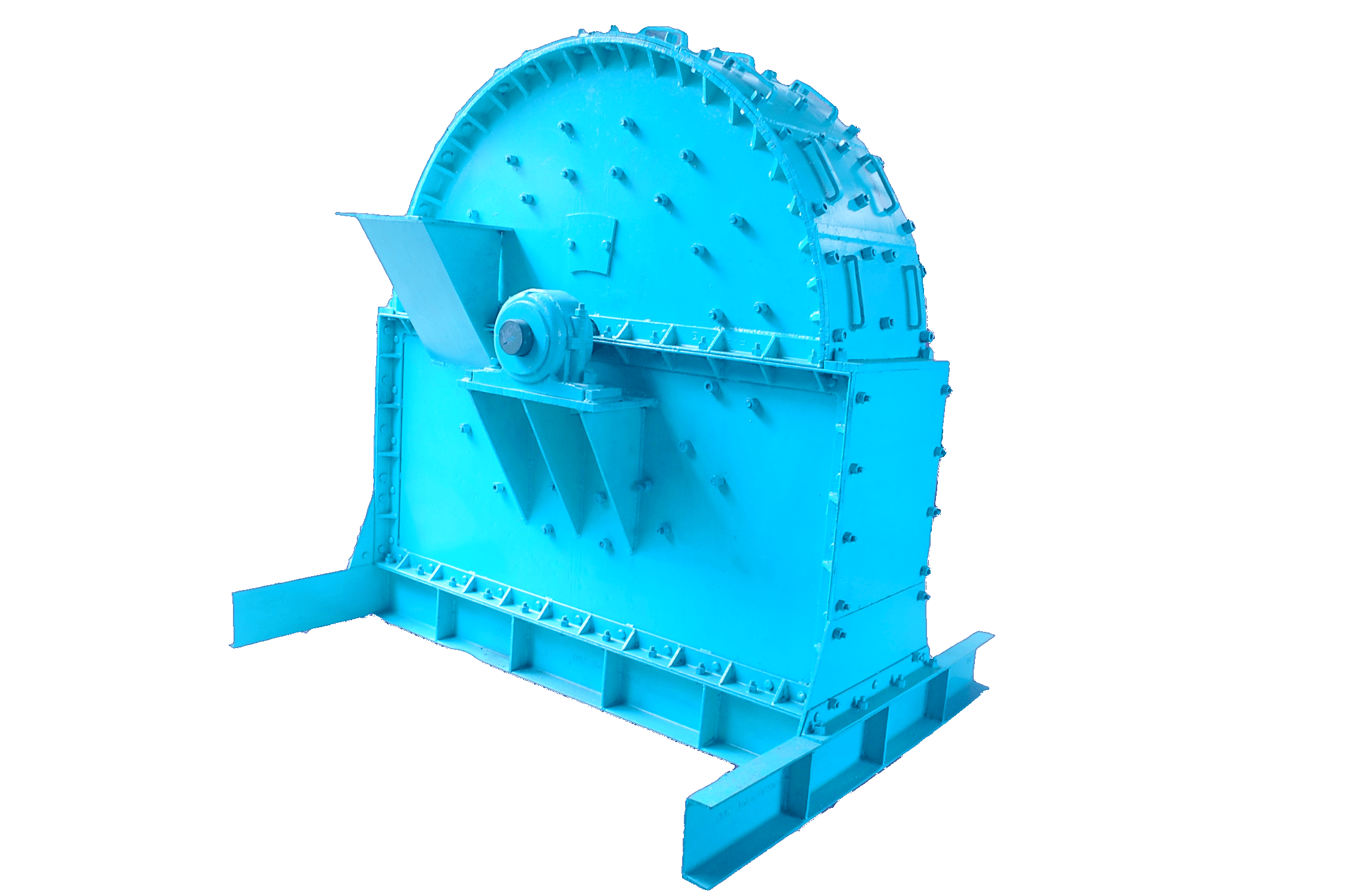

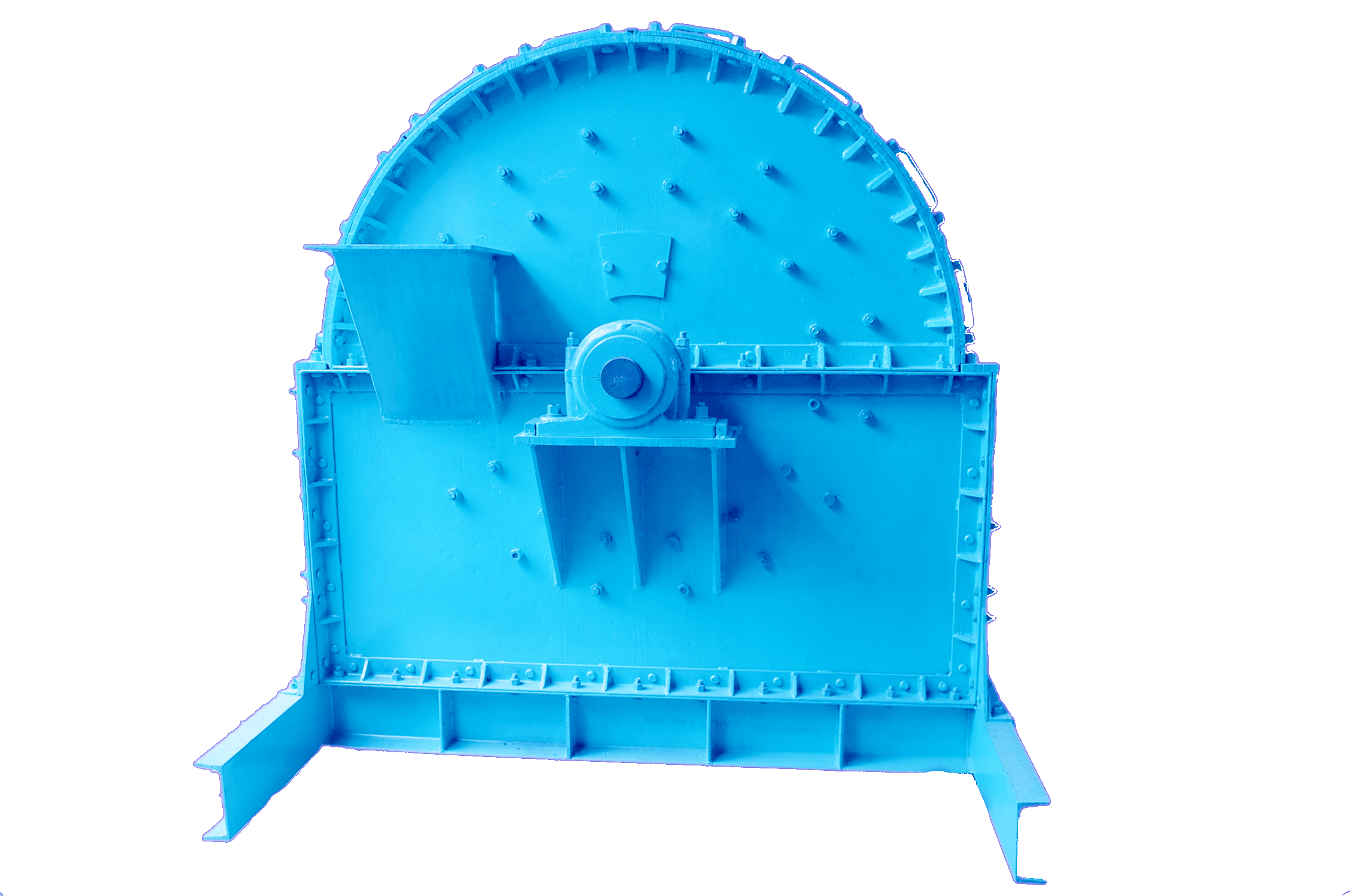

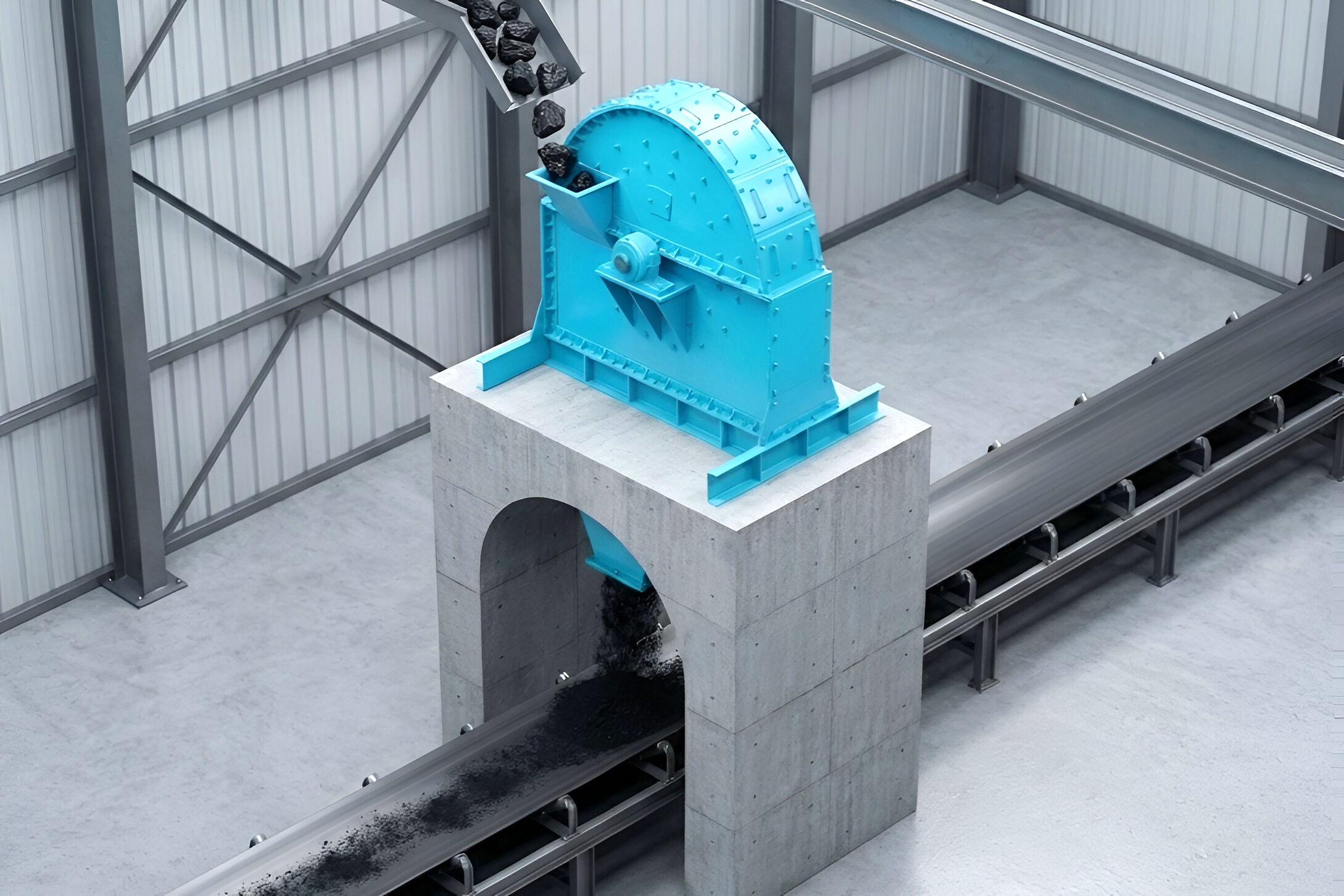

Coal Crusher (5 No. Size) Single Disc

Engineered for precision and consistency, this Single Disc Crusher effectively pulverizes coal into fine granules below 2mm. Featuring a robust 12mm body and 6 Manganese Steel hammers, it is the ideal product for coke oven applications requiring uniform output.

Operational Process Flow

Visualizing the high-speed fine pulverization cycle.

Single Disc Pulverizing Cycle

1. Gravity Feed

Raw coal lumps (up to 125mm) are delivered via the upper conveyor belt and drop directly into the crushing chamber via the top hopper.

2. High-Speed Impact

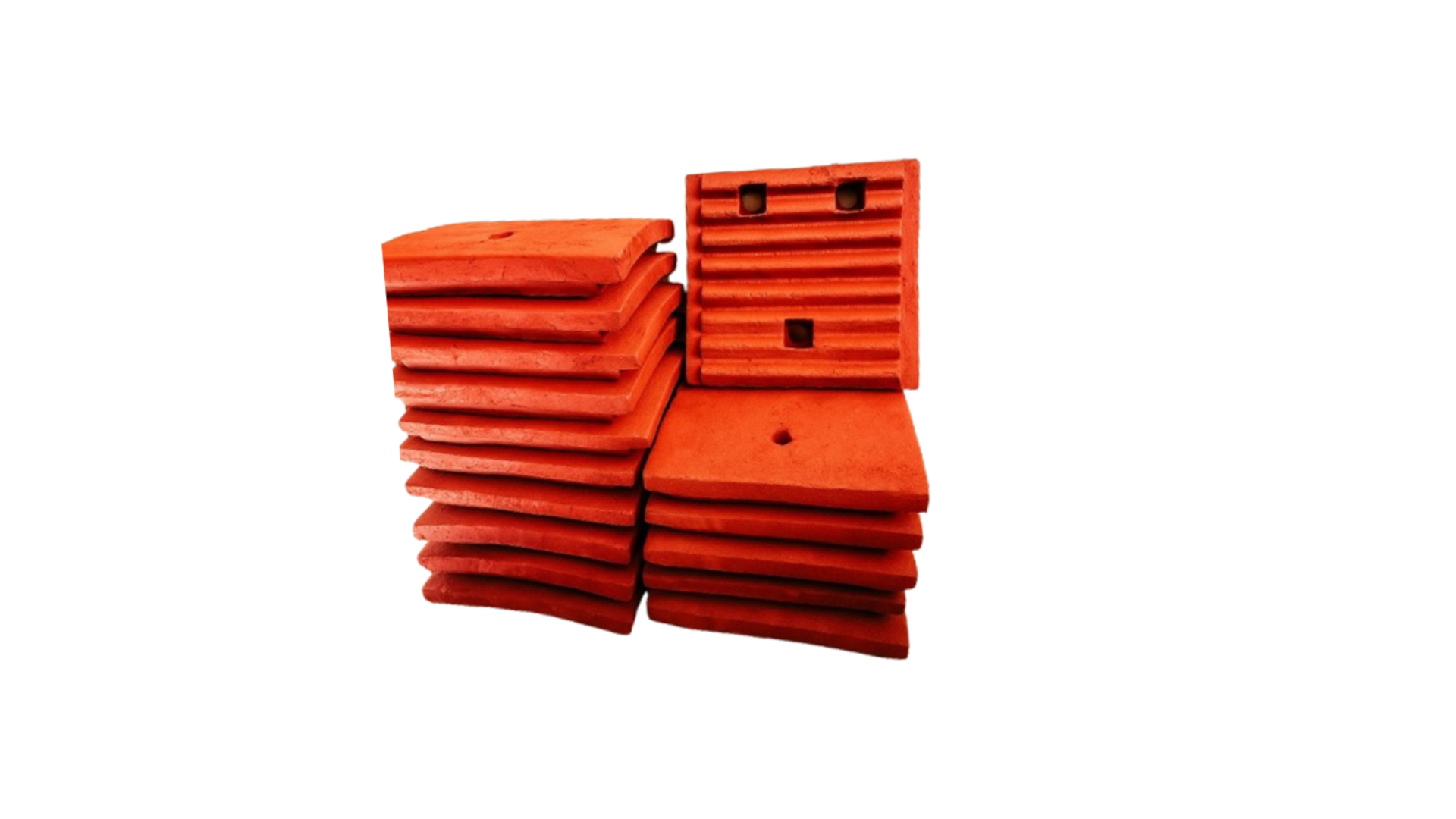

Inside, the Single Disc rotates at high speed. The 6 Manganese Steel hammers impact the coal against the liner plates, shattering it instantly.

3. Fine Discharge (< 2mm)

The pulverized coal is reduced to a fine powder (below 2mm) and discharged onto the lower conveyor belt, ready for the boiler.

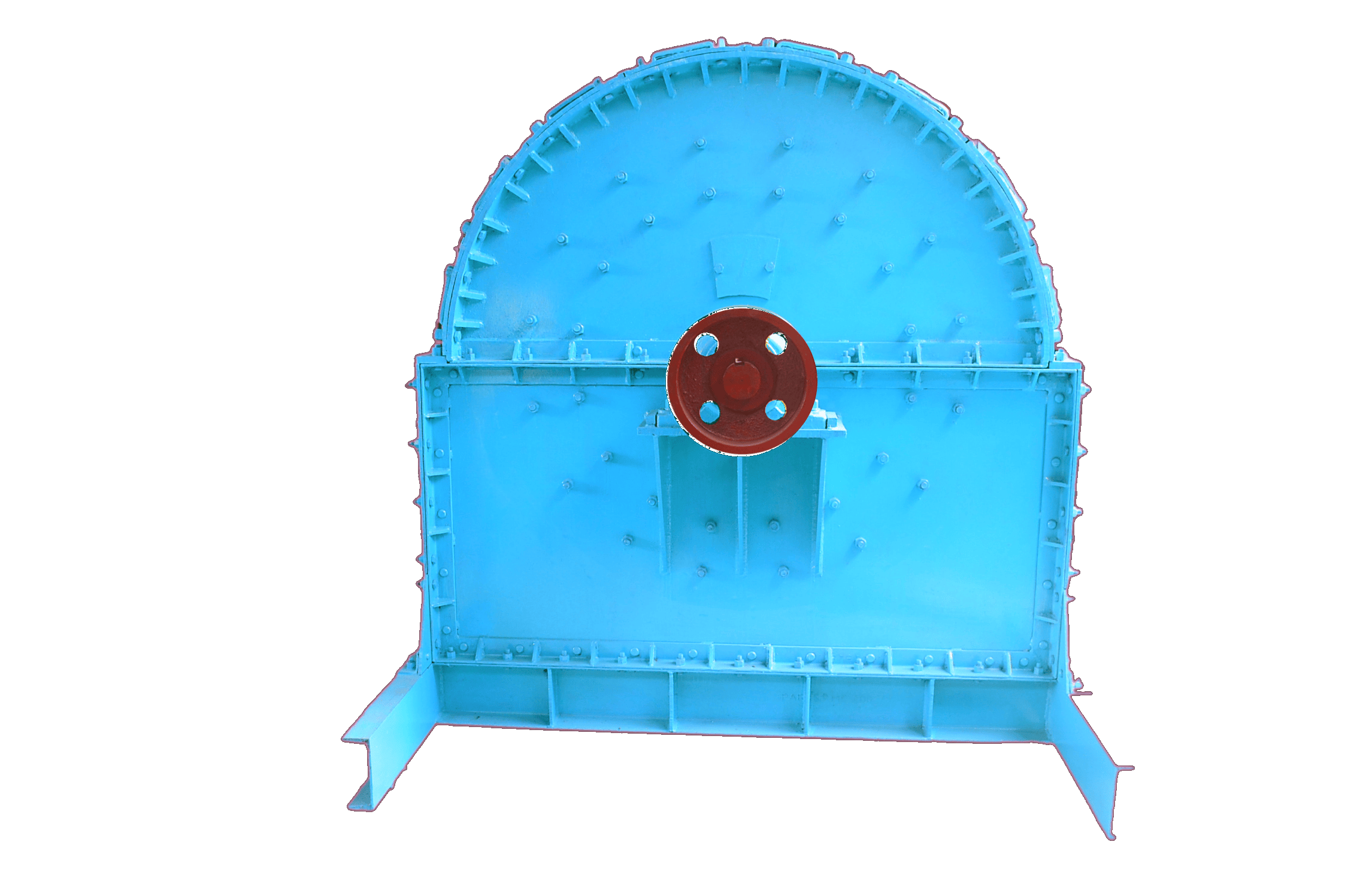

Product Gallery

Visual details of the Single Disc crushing mechanism and internal components.

Common Questions

Specifics about this machine.